Just nu värmer vi tillsammans över 31 000 moderna lägenheter med överskottsvärme.

Befintlig leverantör till Öppen Fjärrvärme? Logga in här

Just nu värmer vi tillsammans över 31 000 moderna lägenheter med överskottsvärme.

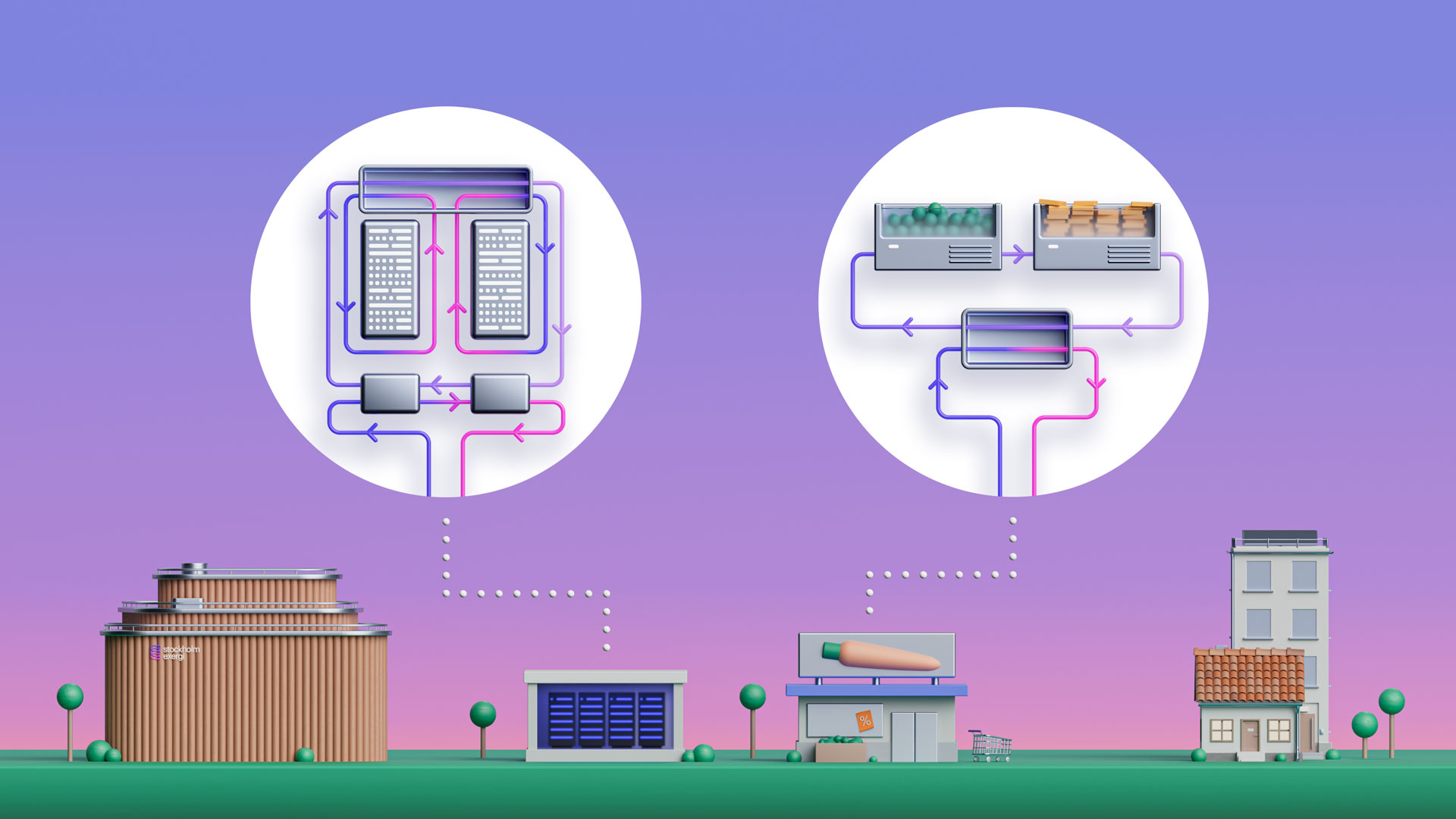

Befintlig leverantör till Öppen Fjärrvärme? Logga in härGenom att återvinna överskottsvärme från bland annat datahallar och livsmedelsbutiker värmer vi tiotusentals lägenheter om vintern. Tillsammans skapar vi ett hållbart Stockholm genom att ta vara på energi som annars skulle gått förlorad.

Stockholm Exergis fjärrvärmenät består av drygt 300 mil rör under marken i Stockholm. Dessutom har vi ett världsunikt fjärrkylanät bestående av ca 30 mil rör. Dessa distributionssystem gör det möjligt att flytta energi från platser med överskott till platser där energin behövs.

Har du ett företag och verksamhet med överskottsvärme som ligger i anslutning till vårt nät kan du sälja sälja energi till oss. Vi kallar det Öppen Fjärrvärme.

Erbjudandet Öppen Fjärrvärme riktar sig främst till datahallar, livsmedelsbutiker och annan industriell verksamhet som genererar överskottsvärme. Som leverantör till Öppen Fjärrvärme omvandlar du en kostnad för kylning till en intäkt genom att sälja din överskottsvärme till Stockholm Exergi till marknadspris.

Återvinning av överskottsvärme genom Öppen Fjärrvärme bidrar till att värme- och kylanläggningar utnyttjas mer effektivt då de blir en del av stadens energisystem. Målet är alltid en ömsesidig lönsamhet och energieffektivitet för såväl leverantörerna som för Stockholm Exergi.

Senast 2030 ska fjärrvärmen i Stockholm produceras till 100 procent av förnybar och återvunnen energi. Som Öppen Fjärrvärmeleverantör är du med och bidrar till ökad resurseffektivitet och minskade klimateffekter.

Tillsammans skapar vi ett hållbart Stockholm genom att ta vara på energi som annars skulle gått förlorad.

Stockholm Exergi ersätter för levererad värme utifrån vad motsvarande värme hade kostat om vi själva producerat den i våra anläggningar. Ersättningsnivån styrs av utomhustemperatur och blir högre vid lägre temperaturer.

Indikativt betalar Stockholm Exergi 2 MSEK årligen för en värmeleverans motsvarande 1 MW. Ersättningsmodellen är indelad i två geografier Norra och Södra Stockholm.

Anpassade avtalsmodeller

Öppen Fjärrvärme har två avtalsmodeller utifrån leverantörernas unika förutsättningar och behov.

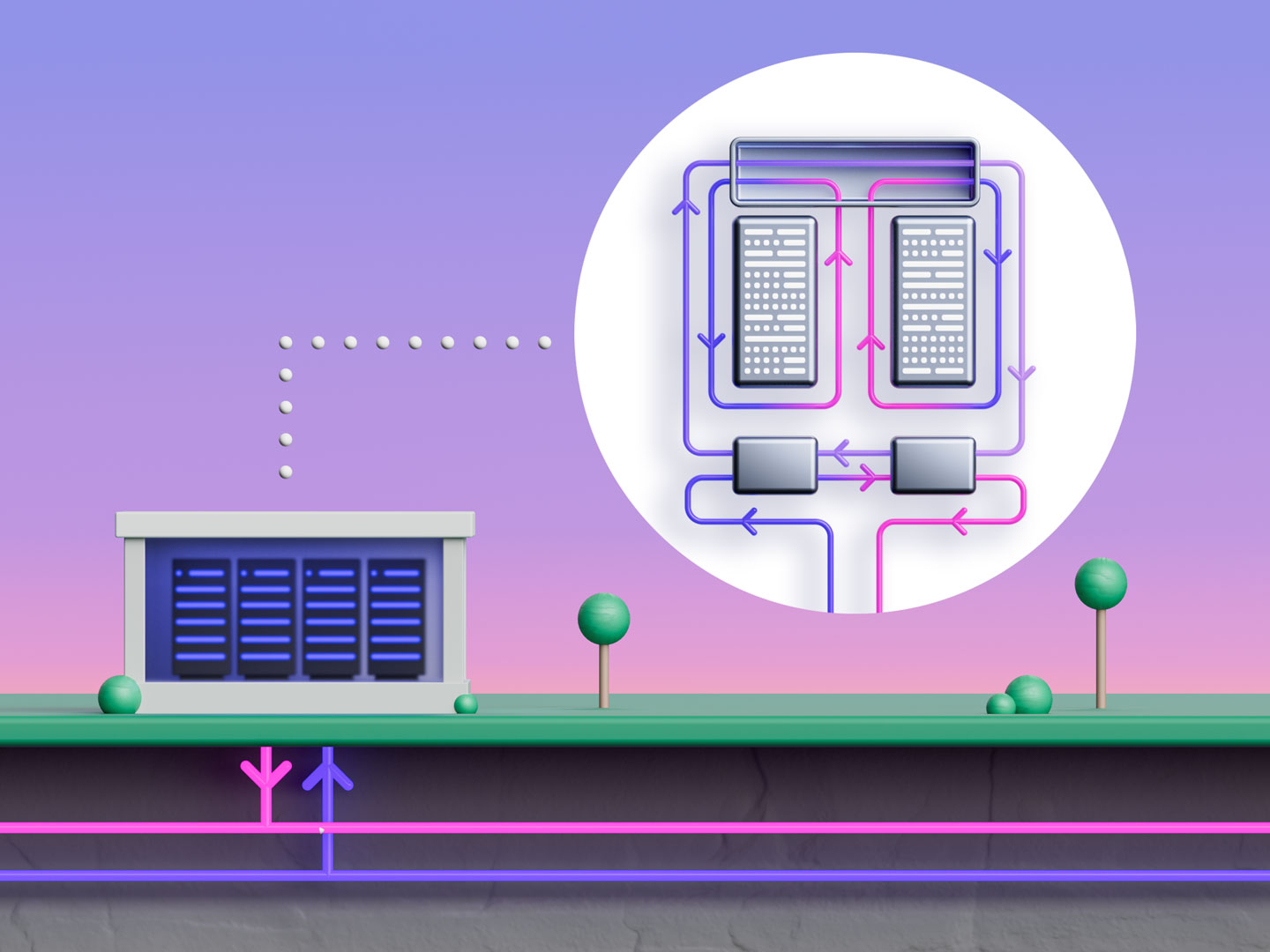

I en datahall finns mängder av servrar som alstrar värme och därför behöver kylas. Oftast görs detta med en kylmaskin, och den bortkylda överskottsvärmen transporteras sedan vidare till ett kyltorn där den fläktas bort.

Genom att istället kyla datahallen med hjälp av en eller flera värmepumpar kan överskottsvärmen levereras till fjärrvärmenätet och användas till uppvärmning av staden istället för att fläktas bort.

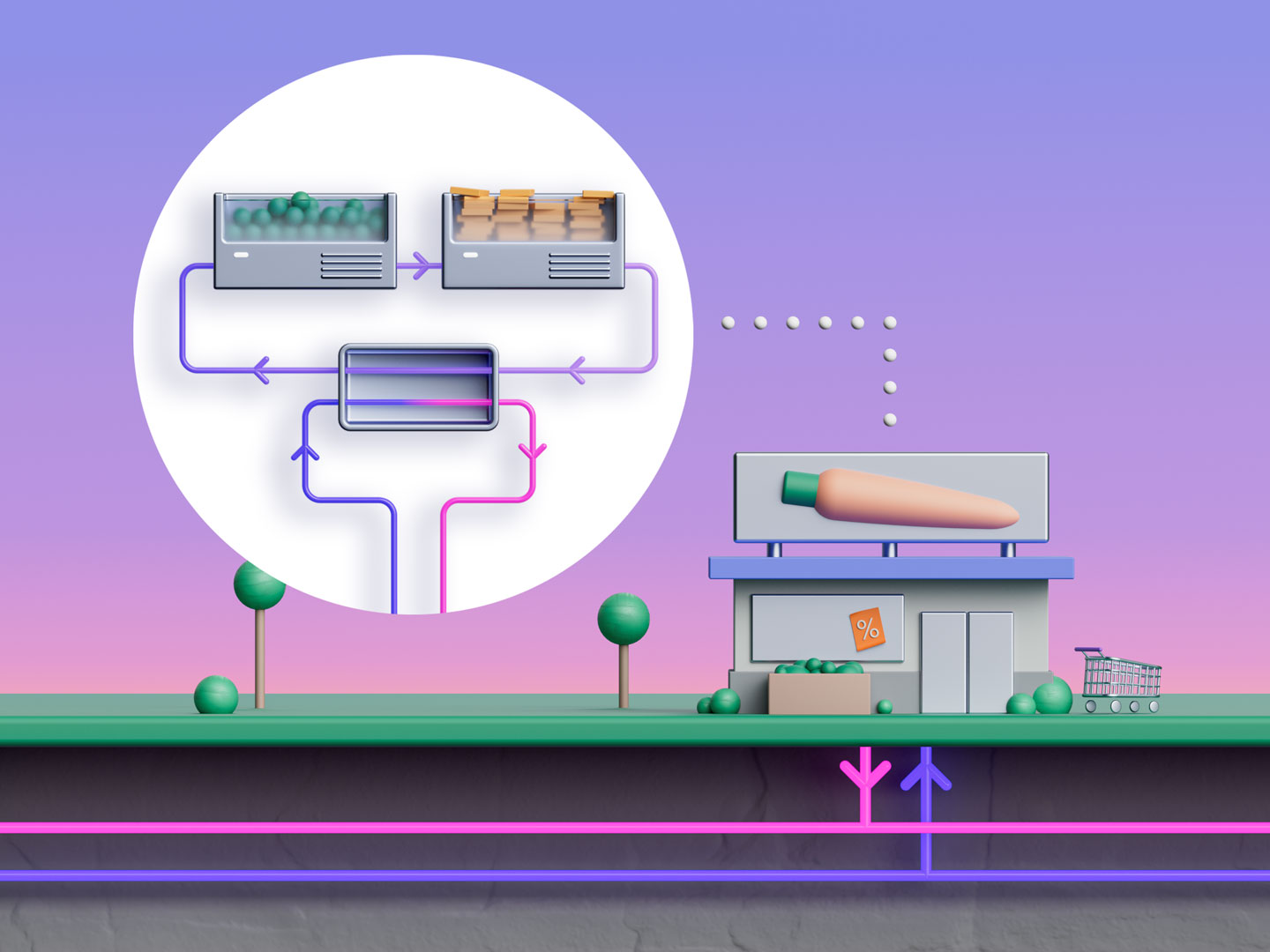

Den viktigaste utgångspunkten med återvinning av värme från livsmedelsbutiker är, förutom ökad lönsamhet, samhällsnyttan som skapas genom att energi som annars skulle gå förlorad nu kan användas av andra.

Moderna anläggningar för butikskyla till kyl och frys kan kopplas direkt mot fjärrvärme- och fjärrkylanätet så att all överskottsvärme kan återvinnas. Värmen vi återvinner räcker redan till att värma tiotusentals lägenheter per år. Du kan hjälpa oss att öka den siffran.

Har du en datahall, en livsmedelsbutik eller annan industriell verksamhet som genererar överskottsvärme? Låt oss titta på om vi kan hjälpa just din verksamhet.

Tomas Esselin

tomas.esselin@stockholmexergi.se

+46 (0)70 993 4314

Med Stockholm Data Parks ökar vi förutsättningarna för storskalig värmeåtervinning i Stockholm ytterligare genom att erbjuda allt som behövs för att bygga stora datahallar i anslutning till vårt fjärrvärmenät. Vi lanserade Stockholm Data Parks i januari 2017, tillsammans med Stockholms stad, Ellevio, Stokab och Invest Stockholm.

Tanken bakom den gemensamma satsningen är att nyttja synergierna mellan Stockholms fjärrvärmenät, pålitlig leverans av förnybar el, och Stockholms position som ett ledande globalt IT-centrum. Vi vill göra Stockholm till centrum för en hållbar datahallsindustri där hallarnas spillvärme återvinns i stadens fjärrvärmenät.

Genom Stockholm Data Parks skapar vi möjlighet för den växande datacenterindustrin, som idag står för runt två procent av världens elkonsumtion, att bli en del av lösningen.

Tack vare värmeåtervinningen kan datahallar i Stockholm Data Parks som använder förnybar el få ett svårslaget lågt klimatavtryck. Därtill sänker datahallarna sin driftskostnad.

När Stockholm Data Parks är fullt utbyggt, kommer värmeåtervinningen från datahallarna att stå för ett betydande tillskott av värme till Stockholm. Det är ett viktigt bidrag till stadens ambition att vara helt fossilfri senast 2040.